Contact Us

Have questions or need assistance with your industrial refrigeration needs?

Our team of experts is ready to help you find the perfect solution for your requirements.

Have questions or need assistance with your industrial refrigeration needs?

Our team of experts is ready to help you find the perfect solution for your requirements.

February 2025

Date: March 2025

Location: Shoprite Riverfields Distribution Centre

Team: CSES, IBControls, EPR, IMC

The Shoprite Riverfields Distribution Centre (DC) recently underwent a comprehensive fault-finding and commissioning phase involving the refrigeration control systems monitored through the EC-Control software and Carel pCO controllers. As part of the final snag list, our team identified critical issues affecting the communication and operational integrity of several fans, sensors, and controllers.

This article provides a breakdown of a specific fault-finding scenario involving the visual diagnostic interface of the EC-Control system and how it was used to isolate and address communication failures between fans and their respective control relays.

Using EC-Control (Version 1.50 Build 425), several inconsistencies were observed in the visual representation of controller and fan status indicators.

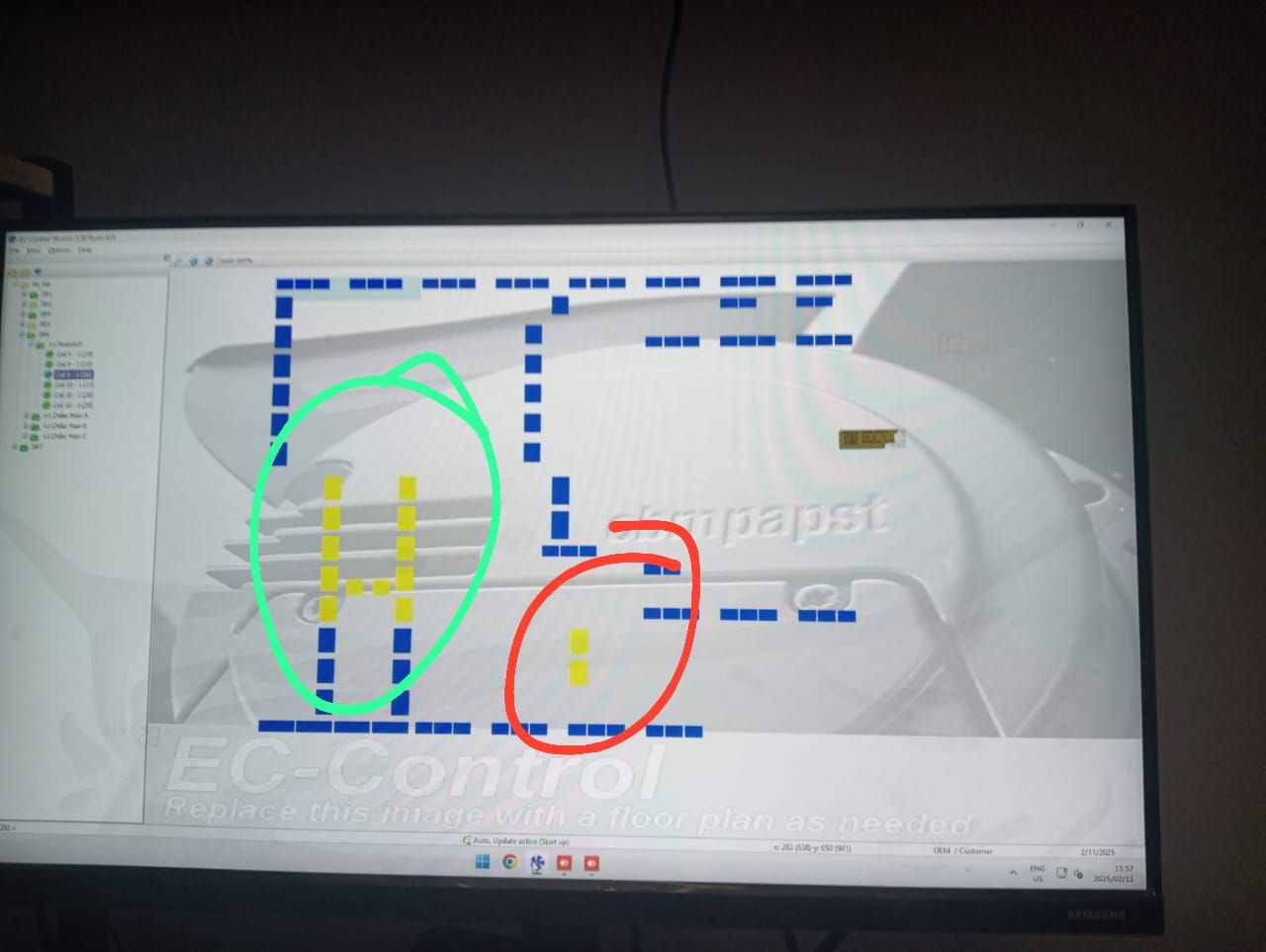

The screenshots attached show two key zones marked out for investigation:

• 🟩 Green Circle: Multiple fans (4 units) appeared yellow, indicating communication failure or signal loss.

• 🔴 Red Circle: One fan within this group also displayed signal failure but was isolated from the group.

These visual cues prompted the team to investigate potential signal transmission faults, miswiring, or configuration errors within the signal relay chain (IO2 → IO3).

The EC-Control interface proved to be an invaluable tool for fault localization:

• Yellow blocks indicated missing speed feedback or signal interruptions.

• Black blocks suggested communication timeout or complete signal loss.

• Blue blocks represented healthy communication and operational status.

This allowed technicians to pinpoint discrepancies without the need to manually trace wiring end-to-end immediately.

Cross-referencing the visual indicators with the official snag list, the following root causes were confirmed:

• DB5 Coil 30 (+1 Chiller Passage): Fan 2 not receiving a speed signal (Fan 1 is fine).

➤ Resolution: Signal relay between IO2 and IO3 was checked for continuity and configuration.

• DB4 Coil 22 (+1 Multitemp): Fans 2, 3, and 4 not receiving signals, while Fan 1 worked correctly.

➤ Resolution: Suspected wiring or IO relay misconfiguration.

• DB4 Coil 32 (+1 Multitemp): Fan 1 not communicating at all.

➤ Resolution: Full rewire and testing planned.

These issues were compounded by previously known faulty fan sets that were marked for future verification.

Technicians followed a staged approach to resolve the issues:

1. Rechecking signal wiring from IO2 to IO3.

2. Verifying correct relay logic and response using EC-Control logs.

3. Inspecting physical wire connections and swapping out any degraded cores.

4. Re-programming the pCO controllers to correct variable mapping errors.

• Real-time visualization tools like EC-Control significantly speed up fault isolation.

• A central snag list helps ensure nothing gets overlooked, especially in complex environments like DCs with over 60 coils and multiple fan banks.

• Standardizing signal relays and implementing robust visual alert systems (e.g., color-coded statuses) improves maintainability and onboarding of new technicians.

This project at Shoprite Riverfields DC serves as a model of how software-drivenRiverfieldss, combined with coordinated onsite expertise, can efficiently resolve complex control system faults. With continuous updaRiverfields the software and hardware layers, the refrigeration system is now fully operational, with robust redundancy and reliable monitoring in place.

📸 Screenshots provided by on-site technician during live diagnostics.

📄 Snag list provided by AMC and CSES engineering teams.