Contact Us

Have questions or need assistance with your industrial refrigeration needs?

Our team of experts is ready to help you find the perfect solution for your requirements.

Have questions or need assistance with your industrial refrigeration needs?

Our team of experts is ready to help you find the perfect solution for your requirements.

March 2025

Client: Clover South Africa

Site: Distribution Centre, Queensburgh

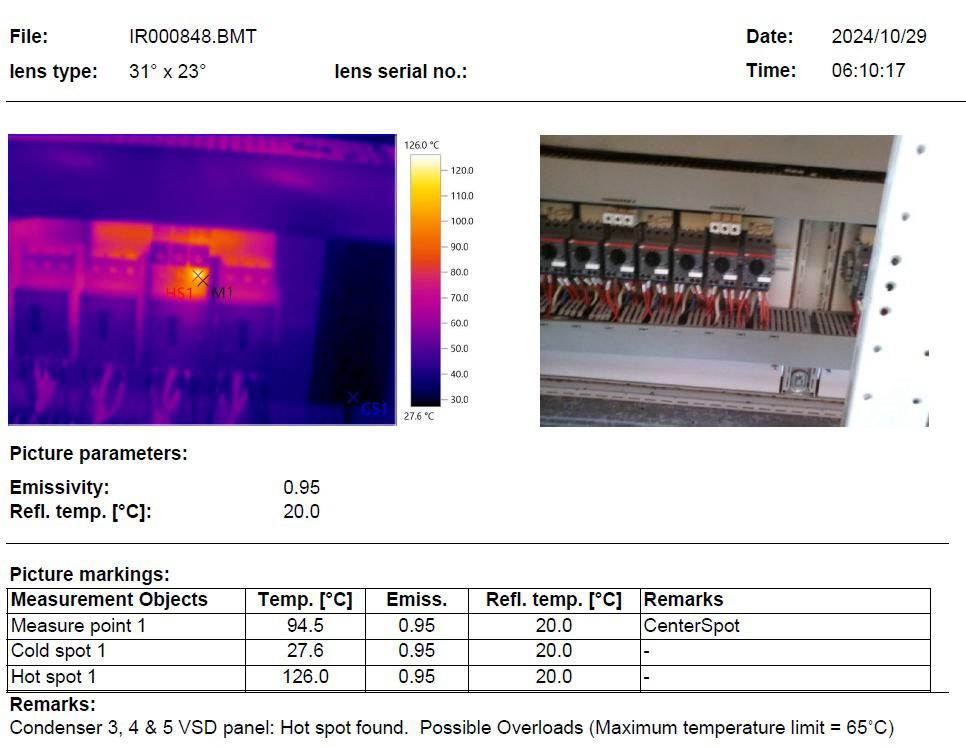

Scope: Preventative Electrical Maintenance, Thermal Scanning, Load Verification

Focus: Ammonia Refrigeration System, Compressor Room, MCC & Condensers

Date: March–April 2025

Clover's Queensburgh DC operates a high-load ammonia-based refrigeration system integral to its cold chain logistics. Our team conducted a preventative maintenance inspection across the facility’s electrical infrastructure — covering compressors, condensers, MCC busbars, and signal/control terminations.

Given the safety-critical nature of ammonia systems and the high uptime required by the client, the goal was to identify potential electrical failures before they occur — especially those that can lead to equipment damage, energy loss, or fire risk.

The preventative inspection revealed several high-risk faults which, if left unattended, could have led to equipment failure, downtime, or panel fires. All faults were logged and submitted to the client for rectification, with priority listed by severity.

Top 3 Recommendations:

In critical infrastructure like cold storage and ammonia plants, preventative maintenance isn’t optional — it’s your insurance against breakdowns and risk. Proactive inspections allow us to catch thermal stress, wiring fatigue, and load irregularities before they cause downtime or damage.