Contact Us

Have questions or need assistance with your industrial refrigeration needs?

Our team of experts is ready to help you find the perfect solution for your requirements.

Have questions or need assistance with your industrial refrigeration needs?

Our team of experts is ready to help you find the perfect solution for your requirements.

May 2025

May 2025

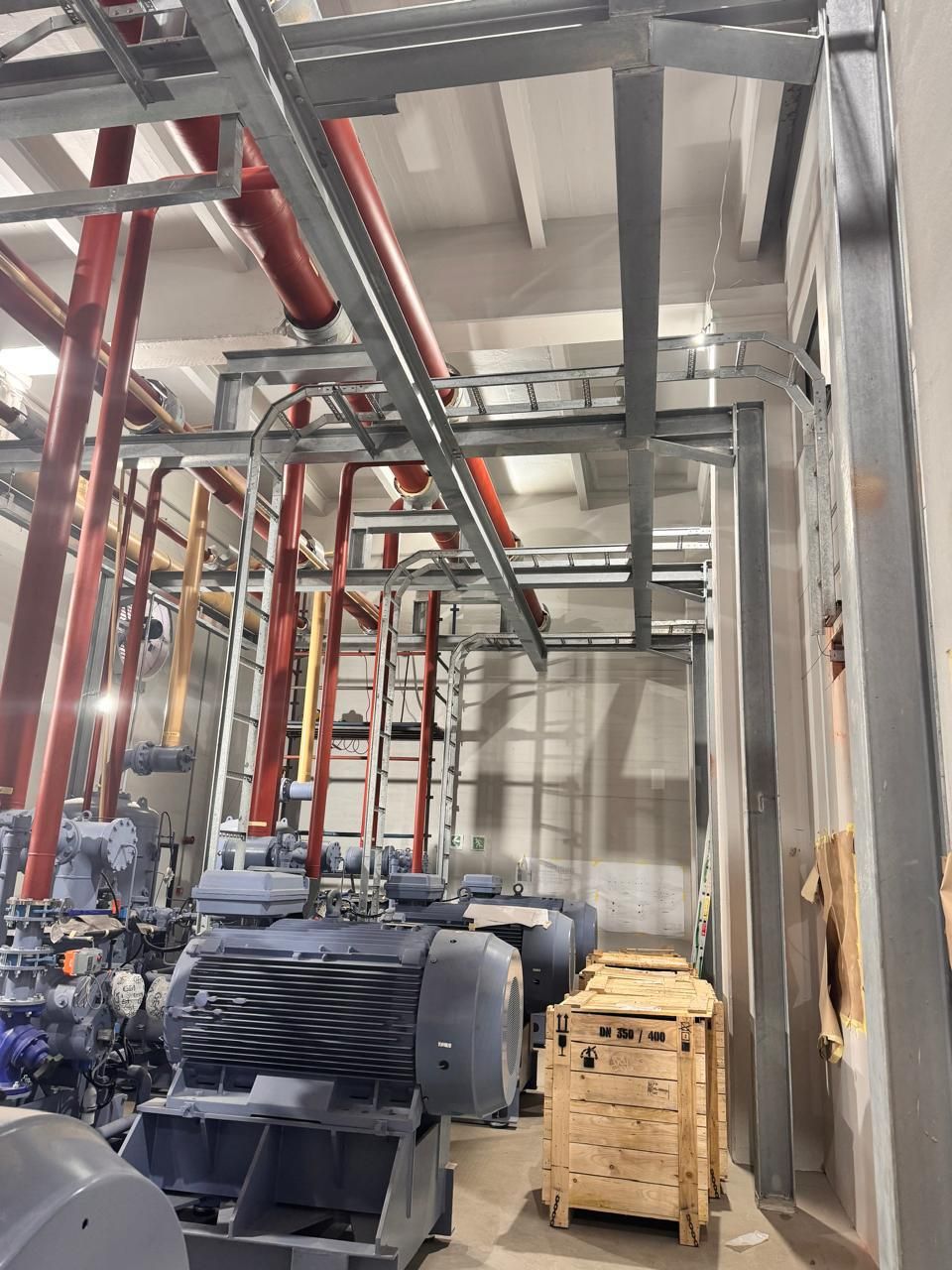

Client: Aspen Pharmacare (Sterile-manufacturing campus)

Scope: LV power, control & earthing for new 17 MWR ammonia refrigeration plant

Phase: First-fix cable management – hot-dip-galvanised ladder, tray & wire-mesh routes; preliminary equipment mounting (condensers & fan motors)

Our team is delivering the electrical backbone for Aspen’s new cooling-as-a-service ammonia plant, a project expected to cut site energy consumption by ≈ 40 %.

The current phase focuses on installing nearly 700 m of cable ladder and tray, earth-bonded to IEC 61537 / SANS 10142, plus dedicated wire-mesh baskets to keep noisy VSD motor feeds away from low-level instrumentation.

| Challenge | Mitigation |

|---|---|

| Congested ceiling below GMP walk-on panels | Layered routes: power ladder top, control tray mid-level, mesh basket bottom |

| 50 kA short-circuit capacity at MCC | 75 mm side-wall ladder with 6 mm splice bars, earth studs every 3 m |

| GMP cleanability | All supports chamfer-ground & lacquer-sealed; no dust-harbouring shelves |

Every radius, earth lug and IP68 gland installed now safeguards Aspen’s GMP production from unplanned downtime later.

By getting the “invisible” infrastructure right first time, we’re helping Aspen realise its sustainability targets without compromising regulatory compliance.

Need similar large-scale refrigeration or GMP-grade electrical work?

Contact the CSES team – we’ll keep the cool chain running.